Recent Advances in Ceramics for Dentistry

Advances in Ceramics for Dentistry – Electric and Magnetic Ceramics, Bioceramics, Ceramics, and Environment. Edited by: Costas Sikalidis. Ceramics are gaining importance as materials used for fillings, crowns, veneers, bridges, dentures, and full tooth replacements as new implants. Ceramics are especially useful in cosmetic dentistry, where the goal is to have a beautiful smile with a natural look. Ceramic materials improved dramatically over the past decade, which, most importantly, made them more durable.

Dental Ceramic Materials Selection & Cementation Protocols

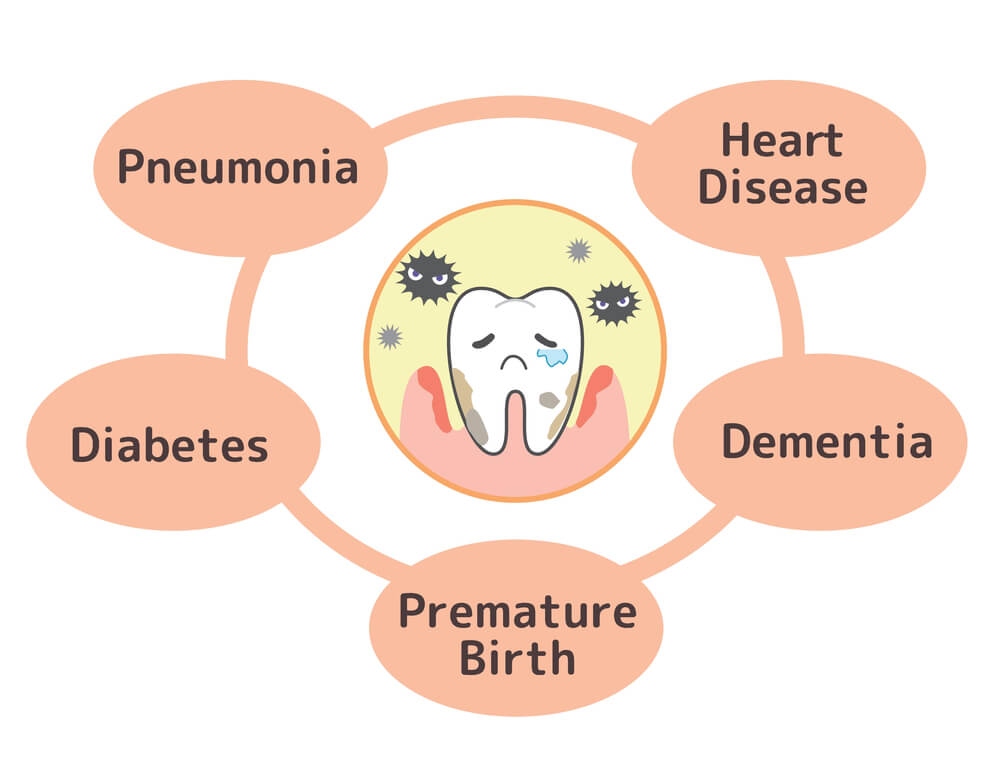

One of the advantages of ceramics is that the materials exposed in the mouth are not metallic. Ceramics may have under-lying metal that provides structural support, yet the surface area that one sees in the mouth is a layer of ceramic material. The materials used to make ceramics do not include mercury.

Mercury Filling Controversy

Controversy arose regarding the use of mercury in making a material used for fillings called “amalgam.” “Amalgam” means a metal mixture. Amalgam consists of 50% mercury mixed with 50% of a powdered alloy of copper, silver, and tin. Mercury is useful because the metal is liquid at room temperature. It is easy for a dentist to mix liquid mercury with powdered alloy to make a fresh batch of filling material when needed for a patient. The mercury binds with the alloy powder causing the mixture to harden.

Amalgam is durable and tough, lasting for many years as a tooth-filling material. Health advocates claim, that trace amounts of mercury leach into the body over time. They think inhaling minute amounts of mercury vapor released from fillings is dangerous and may cause disease. The FDA states clearly that no scientific evidence substantiates the claim that mercury amalgam is a health risk. Consumers need to decide for themselves, how they feel about the potential risk.

Alternative to Mercury Fillings

Many consumers prefer the use of epoxy resin as filling materials or Advances in Ceramics for Dentistry that is used for crowns that completely cover the top of the teeth, over the metal look of amalgam fillings. Others prefer metal but opt for gold, which is completely inert and certainly safe for the human body. However, gold is expensive. This beauty of ceramic materials is why most consumers are choosing them and why they are increasing in popularity.

Ceramics Used for Crowns

There are all ceramic crowns made from composite materials that do not include metals. They have the advantage of being able to match the color of existing teeth. They do not show discoloration from any underlying metal structures. The disadvantage is that all-ceramic crowns are not as strong as those using metal in the construction of the crown.

Crowns made from a combination of ceramics and metal are stronger. The production of these ceramic crowns is a process that fuses porcelain into a metal structure that serves as a foundation. The metals used for the metallic support structure include alloys of gold mixed with palladium or nickel mixed with chromium.

Porcelain itself comes in many varieties including:

- Sintered porcelain made with high heat.

- Feldspathic (using a mineral called feldspar) porcelain reinforced with leucite crystals (made from aluminum tectosilicate and potassium).

- Other types include porcelains based on alumina, magnesia, and zirconia (the stuff used to make artificial diamonds).

Advancements in high-tech materials continue to improve the strength of all-ceramic crowns, including the research into using nanotechnology materials and structures in the design.

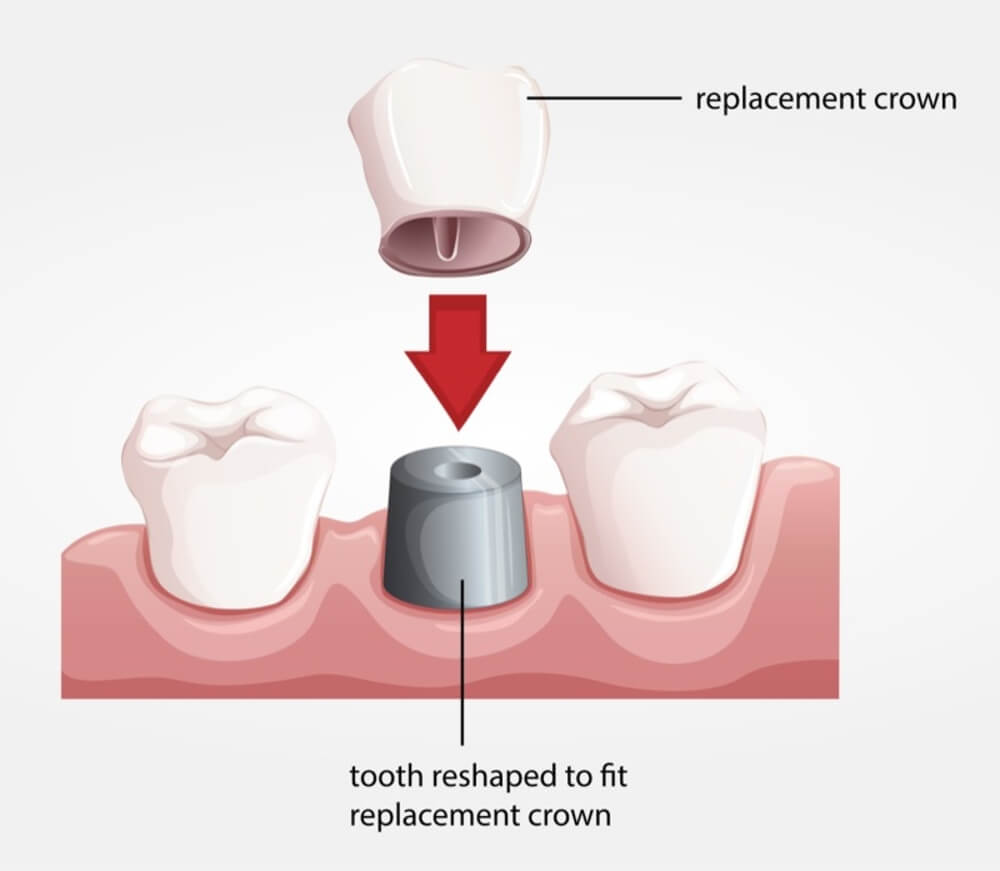

The steps for the installation of a ceramic crown are:

- The dentist prepares the tooth for crown installation.

- The dentist uses a soft, gel-like material to take an impression of the teeth.

- This mold of the teeth, along with information about color-matching the existing teeth, goes to a laboratory that specializes in manufacturing porcelain crowns.

- A temporary cap covers the tooth while waiting for the new crown to arrive.

- A porcelain crown manufactured this way makes a perfect customized fit.

- The dentist installs the new crown, fitting it properly for a comfortable bite, using a strong adhesive that permanently holds it in place.

Ceramics Used for Veneers, Bridges, Dentures, and Tooth Implants

Veneers are thin layers of Advances in Ceramics for Dentistry, installed to cover part of a tooth, to improve its stability and look. Bridges are “fake” teeth filling a gap between other teeth. Bridges are held in place by connecting the bridge to existing teeth.

Dentures are full sets of removable teeth. Tooth implants are replacement teeth that are firmly attached to the jawbone by strong metallic screws.

Ceramics for all these uses include many types of porcelain materials that are the same used to make crowns.

Manufacture of Ceramics

There are four basic types of Advances in Ceramics for Dentistry, which have names according to their manufacturing processes. These ceramics are:

- Glass – Glass-ceramics are made using a “lost wax” process. The ceramic manufacturing lab uses the mold of the teeth to make a wax cast. Then the hot ceramic material is poured into the wax mold, replacing the wax that melts away.

- Slip-cast – This process uses a porous refractory die. A water-based porcelain mixture is poured into the die, which is then heated at high temperatures to remove all the moisture.

- Pressable – These ceramics are made by using high pressure.

- Machineable – These high-tech machines take measurements of the teeth, so no mold is necessary. The machine creates the exact shape needed; using computer-aided design with computer-aided manufacturing (CAD-CAM).

It is an exciting time in cosmetic dentistry. Many important technological Advances in Ceramics for Dentistry help dentists repair and restore teeth, to create perfectly beautiful smiles.